Rotor Corrosion Protection is essential for any rotor blade to maintain a clean aerodynamic surface. Using expensive and time-consuming custom coating processes, rotor blades are left with a matte finish and require continued maintenance.

How Effective are the Rotor Corrosion Protection Coatings?

The rotors Corrosion Coating is widely used in the Aircraft and Equipment industries. They are effective in protecting the Rotor from corrosion. The coatings are applied to the Rotor surface after it has been washed and then dried. There are a variety of coatings that are available and the selection depends on the type of Rotor and the environment in which it will be used.

One of the most common types of rotor Corrosion protection is a Nitrogen-Based coating. This type of coating forms a hard protective barrier that resists tarnishing and corrosion. Another popular type is an Aluminum-Based coating. This type of coating forms a tough protective barrier that also resists staining, discoloration and deterioration.

Rotor corrosion is a progressive and irreversible deterioration of the blade or hub material caused by exposure to moisture, salt mist, acidic gases or liquids, or certain fuels. The most significant cause of rotor corrosion is water vapor.

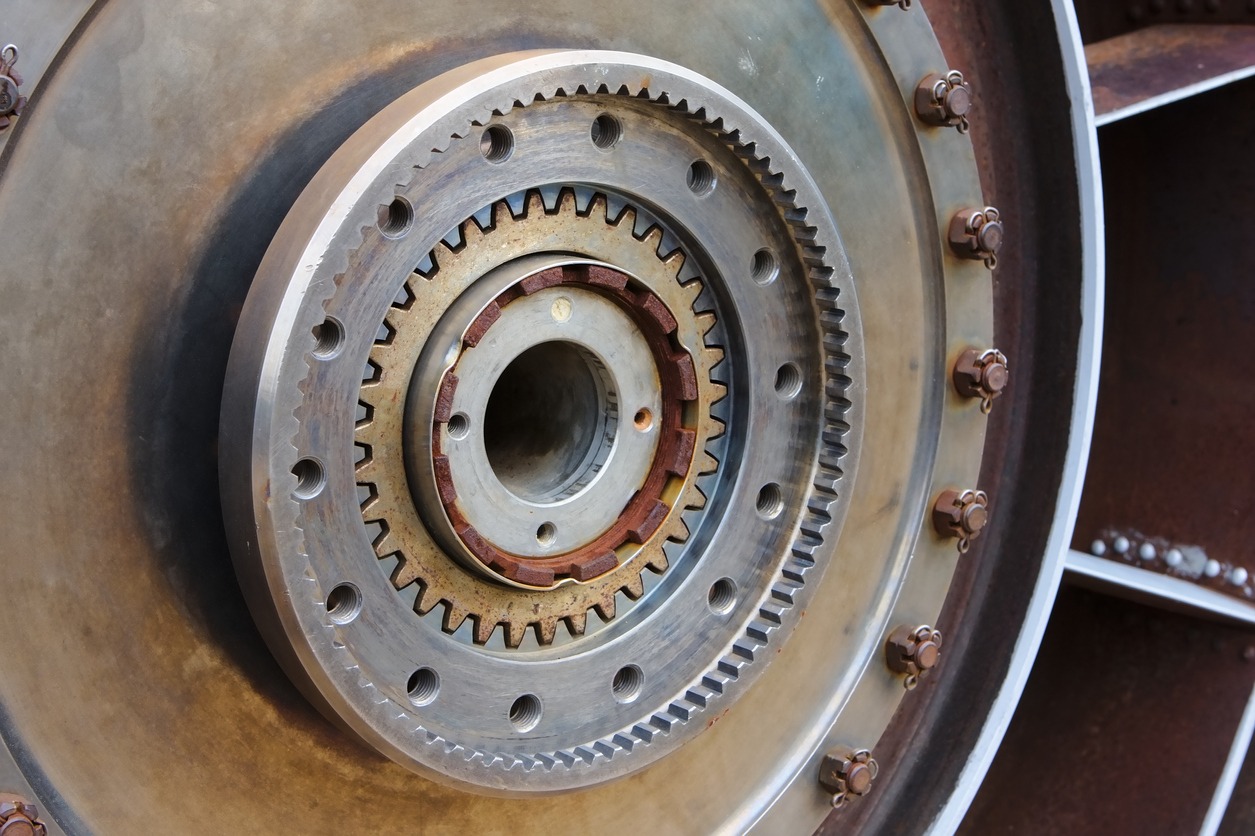

The primary blade surfaces are constantly exposed to the atmosphere and rain while in use. The liquid water droplets deposited on these surfaces react with atmospheric moisture and salts to form corrosive compounds that attack the metal. Corrosive materials also find their way into the air gaps between blades and hub, where they attack other components of the rotor assembly.

In order to prevent rotor corrosion, it is important to understand its causes and how to protect your equipment. There are several common ways to protect rotor blades from moisture and salt mist:

- Use a sealant on the surface of the blades.

- Install a coating on the hub or blades that will resist corrosion.

- Use an anti-corrosion treatment on fuel tanks and other fluid systems near the rotors.

Types of rotor corrosion

The rotor is the main component of a wind turbine that converts the kinetic energy of wind into mechanical energy. The metal blades on a rotor are subjected to extreme conditions, including high temperatures and humidity. This constant exposure to corrosion and other damage can cause the blades to fail prematurely.

There are several types of rotor corrosion that need to be considered when protecting your wind turbine:

- Corrosion is caused by external elements such as the environment and weathering.

- Corrosion is caused by internal elements such as metal-on-metal contact.

- Corrosion is caused by impurities in the metal.

Each type of corrosion has its own specific protection measures that should be taken in order to prevent failure.

Why does rotor corrosion happen

rotor corrosion is a process in which the outer surface of rotors rusts. The most common cause of rotor corrosion is moisture infiltration. Moisture causes the metal to swell, which makes it more susceptible to damage from chemicals and other elements. Other factors that can contribute to rotor corrosion include high temperatures, corrosive substances, and vibration.